Cascade impactor

This article includes a list of references, related reading, or external links, but its sources remain unclear because it lacks inline citations. (October 2024) |

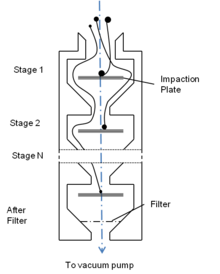

A cascade impactor measures the reach range of a particulate substance as it moves through an opening with the use of aerosol. Cascade impactors are strictly measurement-related devices. In addition to measuring the range of substances moved through an opening by aerosol, the impactor can also be used to determine the particle size of the distributed substance. A cascade impactor collects its samples in a graduated manner. This allows the user to identify the sizes of the substance particles as the particles are distributed from the propellant aerosol source. When the aerosol substance is distributed into the cascade impactor, the substance enters a series of discs designed to collect solids and different particulate matter. The substance is thus collected as it passes through the disc series. Each disc is set in sequence with both the prior and the previous disc. The size of the discs is graduated as well, to properly determine the size of the particulate matter at each stage of the impactor.

An impactor is a device that classifies particles present in a sample of air or gas into known size ranges. It does this by drawing the air sample through a cascade of progressively finer nozzles. The air jets from these nozzles impact on plane sampling surfaces and each stage collects finer particles than its predecessor. The samples may be analysed under the microscope or by any method of chemical analysis that may be suitable for obtaining the mass of material of interest on each stage, e.g. atomic absorption or gas chromatography-mass spectrometry (GC/MS).

All cascade impactors have certain design features in common. By using suitable pumps, jet dimensions can be decreased to the point where the velocity is close to that of sound, enabling particles down to about 0.25 μm to be impacted.

History

[edit]This section needs expansion. You can help by adding to it. (October 2024) |

An early cascade impactor is described in K.R. May's paper in 1945.[1]

See also

[edit]- Andersen sampler – A type of cascade impactor that measures viable bioaerosols

- Particulate matter sampler

- Aerosol impaction

References

[edit]- ^ May, K. R. (1945). "The Cascade Impactor: An Instrument for Sampling Coarse Aerosols". Journal of Scientific Instruments. 22 (10): 187–195. Bibcode:1945JScI...22..187M. doi:10.1088/0950-7671/22/10/303.

Further reading

[edit]- Dunbar, Craig; Mitchell, Jolyon (2005). "Analysis of Cascade Impactor Mass Distributions". Journal of Aerosol Medicine. 18 (4): 439–451. doi:10.1089/jam.2005.18.439. PMID 16379619.

- Newton, G.J.; Raabe, O.G.; Mokler, B.V. (1977). "Cascade impactor design and performance". Journal of Aerosol Science. 8 (5): 339–347. Bibcode:1977JAerS...8..339N. doi:10.1016/0021-8502(77)90021-0.

- Mercer, T.T.; Tillery, M.I.; Newton, G.J. (1970). "A multi-stage, low flow rate cascade impactor". Journal of Aerosol Science. 1 (1): 9–15. Bibcode:1970JAerS...1....9M. doi:10.1016/0021-8502(70)90024-8.

- Nichols, S. C.; Mitchell, J. P.; Shelton, C. M.; Roberts, D. L. (2013). "Good Cascade Impactor Practice (GCIP) and Considerations for "In-Use" Specifications". AAPS Pharmscitech. 14 (1): 375–390. doi:10.1208/s12249-012-9905-1. PMC 3581645. PMID 23344853.

- "A Novel Size-Selective Airborne Particle Size Fractionating Instrument for Health Risk Evaluation". The Annals of Occupational Hygiene. 2009. doi:10.1093/annhyg/mep002.